Metal Spinning Products & Services

FREE Quotes | 50+ Years of Experience | Family Owned

FREE Quotes 50+ Years of Experience Family Owned

Request An Estimate

From Prototyping to Production

Butler Metal Spinning Corp specializes in both prototyping and extended production runs for a wide range of products. We are equipped to handle nearly any material from 10-gauge steel to brass, accommodating circle shearing up to 120”.

We also offer light fabrication and assembly to finish your metal spun products. This includes punching, pressing, rolling, welding, cutting and painting. Expanded services include plasma, water-jet and laser cutting, as well as heat treating, anodizing, plating and other special fabrications.

When considering the right craftsman and manufacturing approach for your project, consider the following benefits of the tooling methods used in metal spinning provide:

- Quick turnaround

- Flexibility in tooling provides ease of design change (dependent on volume, tolerance and the capability of the part needed)

- Tolerances can be adjusted as necessary

- Typical tolerances for metal spinning are .030” though higher tolerances are possible

Basic Geometries

These standard dimensions are general guidelines, not hard rules, and are material type and thickness dependent. Call or email

with your particular details to see how we can work for you.

Parabolic Nose Shape

General guidelines:

OD minimum / maximum: 2" – 40”

Height maximum: 40″

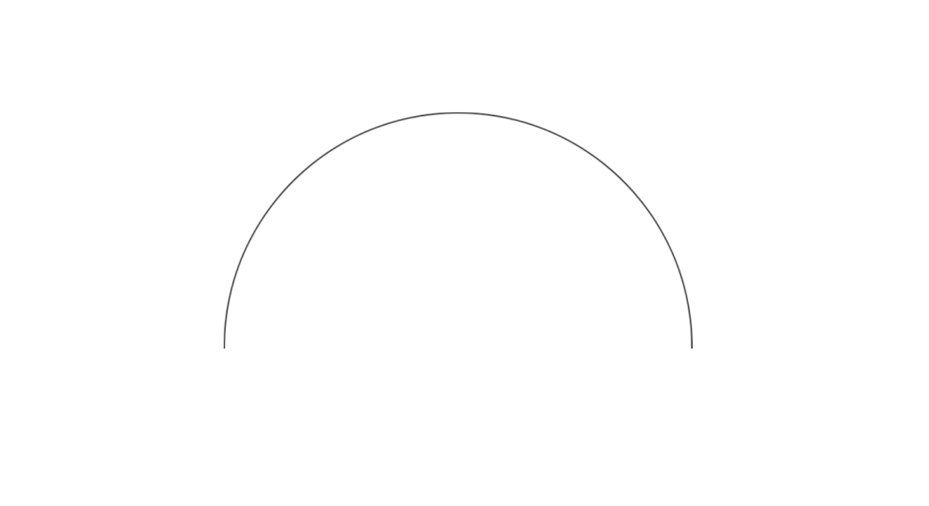

Hemisphere

General guidelines:

OD minimum/maximum: 1” – 36”

Height maximum: 18”

Radius = half the diameter

Catalog Sizes: 3”, 4”, 4.5”, 5.5”, 6”, 10”, 12”, 20”

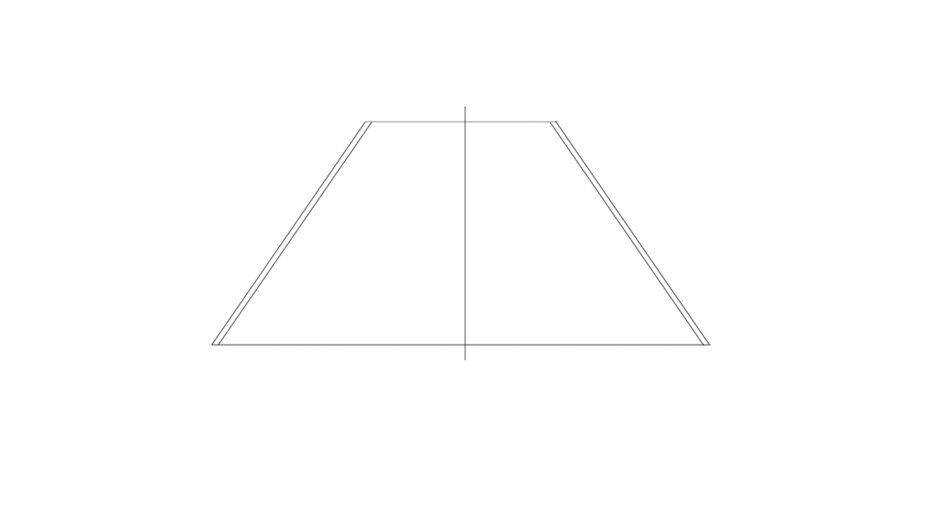

Cone

General guidelines:

OD minimum / maximum: 2” – 58”

Height maximum = ODx2 or maximum 36”

Minimum corner radius > material thickness

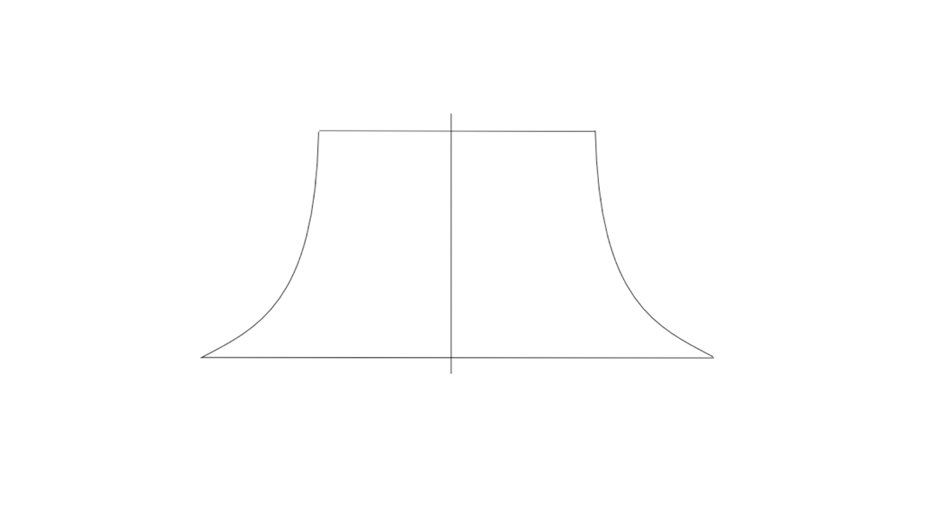

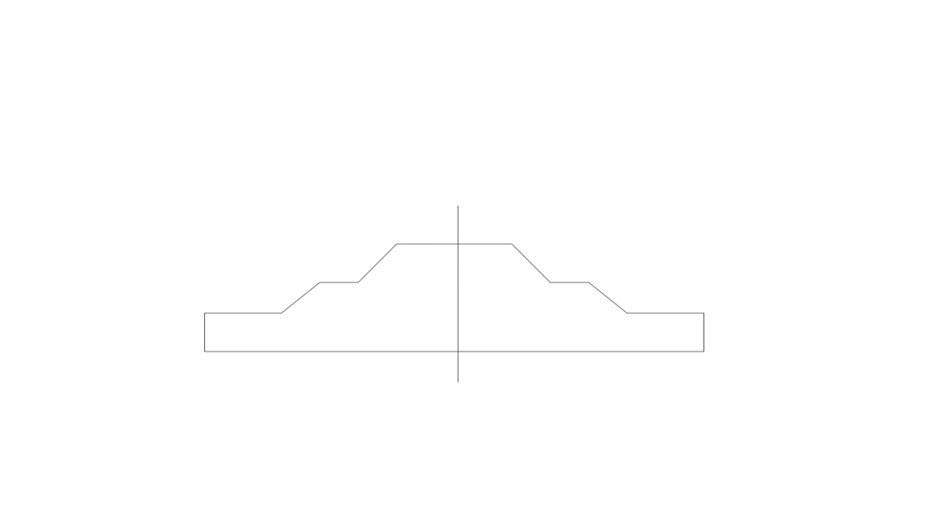

Venturi

General guidelines:

ID minimum / maximum of the: 6” – 40”

Height < 40% of the ID

Blank size maximum: 120”

View more

Share On: